Unpacking Coldfed | Understanding Its Role, Uses, and Industries

Innovation has always helped push industries forward, creating new methods and techniques to address complex problems and boost efficiency. Of all the innovations, “coldfed” stands out as a fascinating concept that’s getting noticed in a wide range of areas. What exactly is Coldfeeding? What is its significance, and how crucial? If you’re new to the concept or interested in its application, this guide will explain the meaning of cold-fed and how it functions, and how it can be used in various industries.

What is Coldfed?

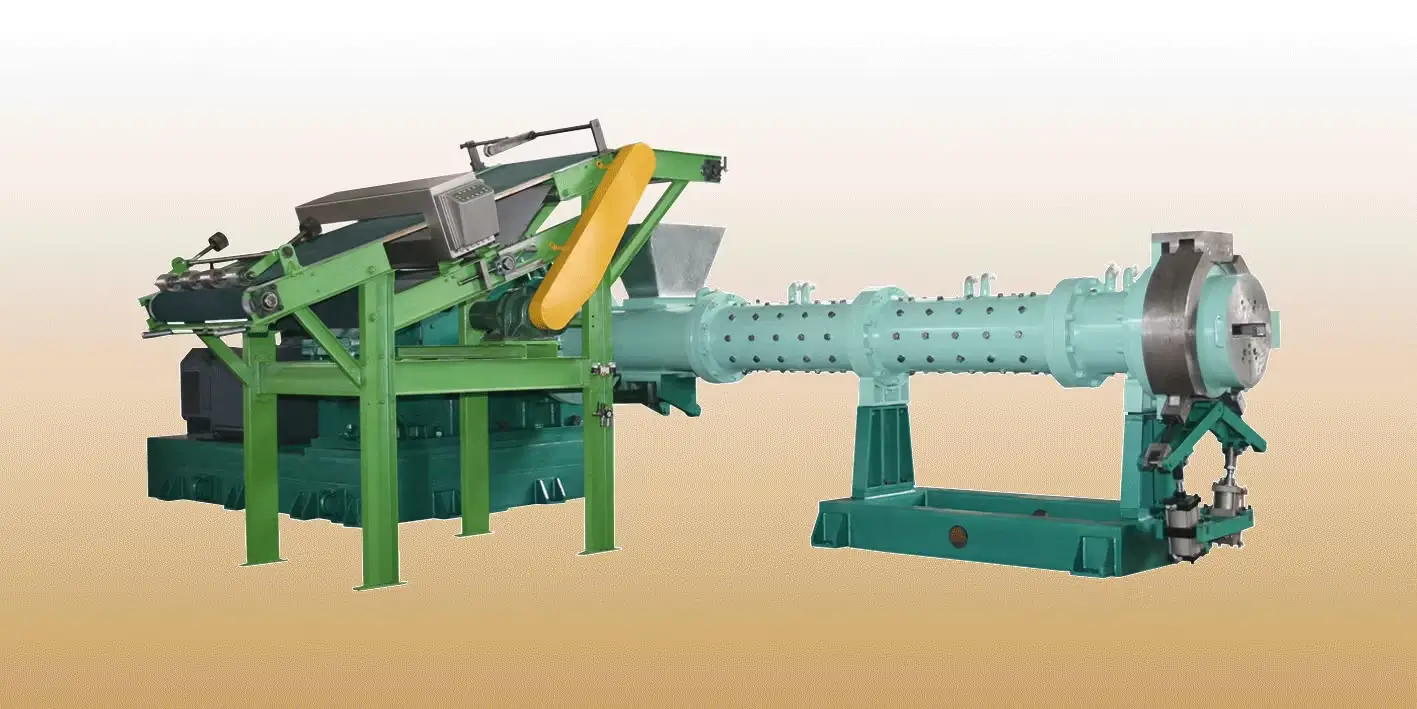

Cold-fed refers to a procedure or method by which materials, like products, resources, or even materials, are inserted into a particular machine or system in a cold condition. It is commonly employed in manufacturing and industrial processes in which controlling temperature is essential for ensuring quality and efficiency. Contrary to hot-fed processes, cold-fed methods typically involve the introduction of materials that can be at room temperature or purposefully cooled to guarantee maximum performance throughout the production process.

The concept applies to many different scenarios, including cold-fed extrusion of rubber for manufacturing, to systems that feed cold for agricultural or other industrial applications. The versatility and flexibility of this method have become an important instrument for optimizing workflows where heat management plays an essential part.

The Significance of Coldfed in Modern Processes

At first sight, the notion of introducing materials into a machine while it is cold might seem like a simple fix. But the implications of this technique are extensive. Here are some of the reasons Cold feeding methods are crucial:

Enhanced Product Control

Processes that use cold feed allow manufacturers to be in control of how their materials behave in the course of fabrication. For instance, when it comes to the manufacturing of plastic or rubber, cold feeding makes sure that the material is not subject to excessive melting or deformation, which could compromise the quality of the product.

Energy Efficiency

Through reducing the dependence on heating up or keeping temperatures high, cold-fed systems can help save energy. This is beneficial to manufacturers financially and helps to achieve sustainable goals for the world by reducing energy consumption overall.

Precise Scaling and Adaptability

Cold feeding permits industries and manufacturers to manage many input materials without having to change the workflows they have in place. This makes it simpler to increase the size of operations or adjust processes to handle different raw materials.

Improved Safety Protocols

Processes that depend on hot-fed systems could create significant risk, such as injuries to equipment or burns. Cold-fed systems reduce these risks, creating safer environments for workers and increasing compliance with safety rules in workplaces.

Key Applications of Coldfed Processes

Cold-fed technologies have gained popularity in a wide range of industries, offering customised solutions to meet their demands. Here’s a look at the areas in which Coldfeding is becoming a necessity

Rubber and Plastic Manufacturing

A single of the popular areas of cold forming is the plastic and rubber manufacturing industry, particularly in extrusion processes. Extrusion of cold-fed rubber involves feeding pre-cooled rubber into extrusion machines, which prevents excessive vulcanization or distortion. Its advantages include:

- Uniform surface finishes.

- Reduction of material waste.

- Consistent dimensional accuracy.

For example, when making top-quality automotive seals or parts, Coldfed extrusion makes sure that the rubber will maintain its structure throughout the entire process.

Agriculture and Food Processing

The cold feeding system is extensively used in agriculture, especially in the feeding of livestock or optimizing irrigation systems. By managing the temperature of feed or water, farmers can regulate the health and efficiency of animals or crops. In the food processing industry, cold-fed technology makes sure that delicate ingredients are introduced into the production system without harming or destroying their nutrients.

Pharmaceutical Industry

Temperature is a key factor in the production of pharmaceuticals, especially when it comes to handling delicate compounds. Cold-fed systems make sure that active ingredients are in good condition and efficient throughout the manufacturing process, thus minimizing the chance of contamination or degradation.

Metal and Powder Processing

Industries in the fields of metallurgy and powder production employ cold-fed methods to manage substances that require exact thermal control during moulding or construction. For instance, cold-fed steel extrusion is used to make robust, lightweight components for the automotive and aerospace industries.

Recycling and Waste Management

Cold-fed processes are utilized in recycling facilities to help speed up the decomposition of materials like glass or plastic. The introduction of materials at lower temperatures helps avoid issues of excessive heat during separation or sorting.

Benefits of Coldfed Systems

To understand why cold-fed processes are regarded as revolutionary, it is essential to look at their advantages. When switching to a cold-fed process industry can:

Cost Savings

The reduction in energy consumption can translate directly into savings. If you are looking to reduce operating costs without sacrificing efficiency, cold-fed systems can be an attractive option.

Environmental Healing

Sustainability is now a major industry standard, and energy-efficient processes like Coldfeeding align perfectly with environmental goals. Through reducing carbon emissions and the dependence on energy, cold-fed farming encourages greener methods of production.

Product Consistency

Industries that depend on critical batch quality, be it food, pharmaceuticals, or cosmetics-codded methods have the advantage of offering reliable consistency. Minor variations could result in large financial losses, but uniform temperatures ensure the integrity of supply chains.

Versatility

Though initially thought to serve specialized applications, modern cold-fed systems can adapt to a variety of processing requirements. This flexibility allows operations to be flexible as the demands of industry change.

Challenges of Implementing Coldfed Processes

While cold-fed methods provide a variety of advantages, their implementation does have a few challenges that companies have to take into consideration:

Upfront Investments

Cold-fed machines may need more capital investment than conventional systems. Retrofitting equipment that is already in use to accommodate cold-fed technology is also costly.

Complexity in Adoption

For companies that are already utilizing heating-dependent infrastructure, the transition to cold-fed systems can be difficult. Training staff members and revamping processes can take a lot of time.

Specific Material Needs

Certain materials may not be able to respond well to cold-fed processes, making them less suitable for use in all scenarios.

The Future of Coldfed Technology

The good news is that, as technological advancements continue to advance, cold-fed systems are becoming more readily available and improved. Thanks to advances in automation and thermal management, the efficiency and ROI on investment from cold-fed processes are poised to continue to improve.

The advancements in machine learning and artificial intelligence are changing cold-fed systems, providing predictive maintenance as well as real-time temperature tracking in order to optimize the efficiency of operations. For companies that focus on quality and sustainability, the future is bound to techniques like cold feeding.

Conclusion

Coldfed is much more than an improvement in technology. It’s also a step towards achieving higher levels of safety, control and efficiency across various industries. In manufacturing or agriculture, or pharmaceuticals, knowing the intricacies of cold-fed systems opens up a whole new set of possibilities to improve processes and reduce costs.

If they invest in cold-fed technology now, businesses can prepare their operations to meet the demands and challenges of the future. If you’re considering the use of cold-fed into your business, now is the best time to investigate the promising benefits of this revolutionary method.

More to Read: Luftanlegg